Excavators Insights: What Drives These Mechanisms Function?

Excavation machines are marvels of modern engineering, playing a crucial role in building, resource extraction, and tearing down projects globally. These mighty machines are crafted to bore, lift, and move materials with accuracy and effectiveness. To fully understand what makes an excavator operate, it's crucial to examine its basic parts. All component works in concert to deliver the amazing functionality that these machines are known for.

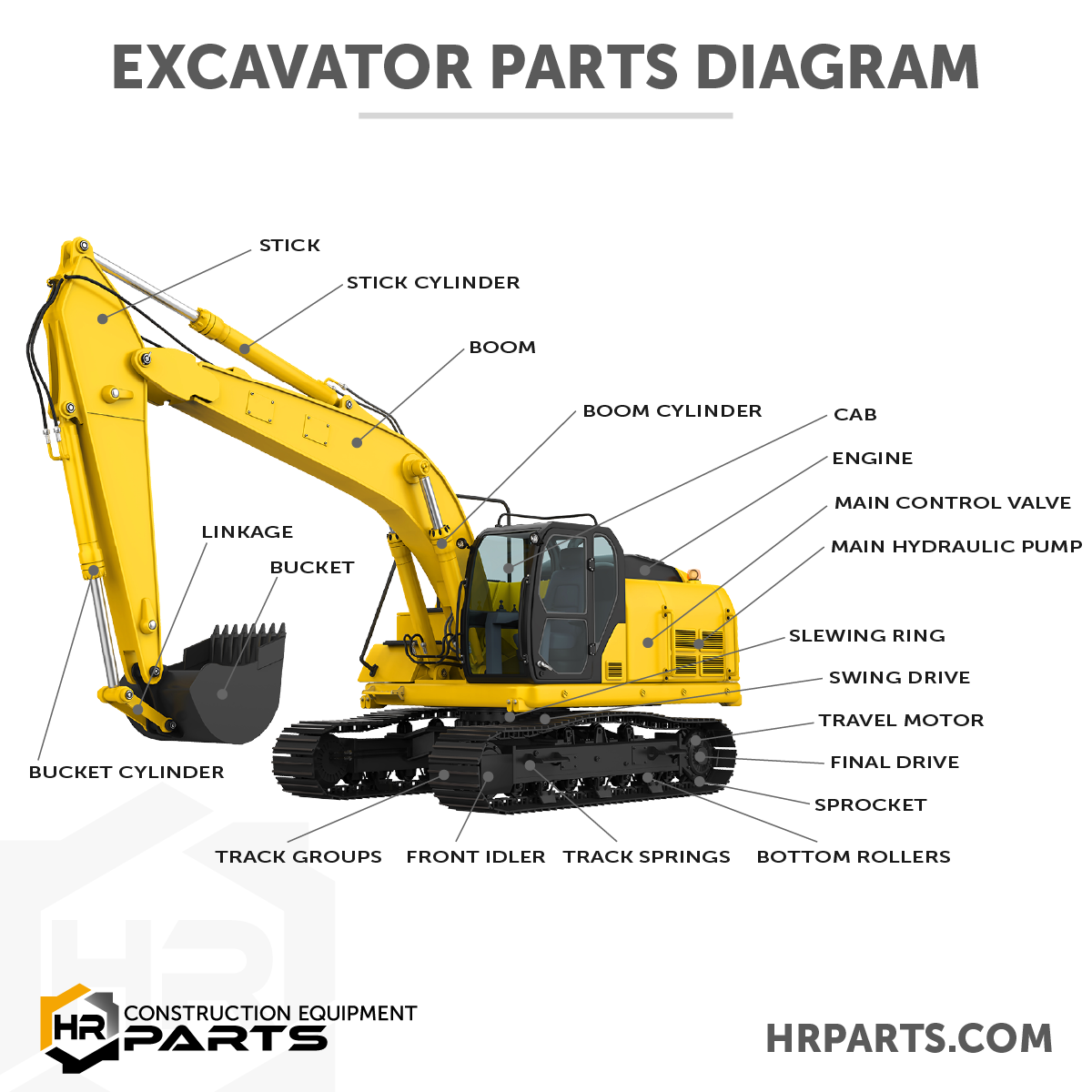

At the center of each excavator lies a blend of hydraulic systems, mechanical components, and state-of-the-art technology. From the robust undercarriage to the flexible boom and bucket, every component contributes to the overall performance and adaptability of the excavator. By inspecting these parts thoroughly, we can gain insightful knowledge into how they work together to tackle some of the hardest jobs on location.

Key Components of Excavation Machines

Excavators are intricate machines designed for a variety of intensive tasks, and their efficiency relies heavily on several critical components. The main part of the excavator is the undercarriage, which includes the tracks or wheels that provide mobility and support. The frame supports the weight of the machine and enables it to traverse different terrains. A robust undercarriage ensures the excavator can perform its tasks without sacrificing stability.

Moreover, an integral component is the house, which contains the operator's enclosure and the arm, link, and attachment system. The house swivels 360 degrees, allowing the operator to have total flexibility in operating the machine. Inside the cabin, various controls enable precise handling and operation of the boom and attachments, such as shovels or cutting implements. This part is critical for the productivity of the excavator as it directly influences how efficiently the machine can operate.

In conclusion, the attachment system includes the arm, arm, and grabber. The boom extends from the house and is essential for reaching into materials. The arm attaches the boom to the bucket, providing the necessary movement to lift, gather, and dispose of materials. Each of these components works in harmony to allow the excavator to perform tasks effectively, such as excavating ditches, moving earth, and tearing down constructions. Comprehending these basic parts helps in valuing how excavators function optimally in diverse construction and mining projects.

The Way Excavator Parts Work In Unison

Excavators are highly engineered machines that feature various essential parts, that work together to execute various tasks. cat parts acts as the base for the excavator, providing support and movement. It includes wheels and tracks that enable the machine to navigate different terrains. When the undercarriage operates, it allows the superstructure to pivot and adjust its position, enhancing the excavator's capabilities.

The hydraulic mechanism is a further critical component that powers the excavator's functionality. Hydraulic fluid is pumped through lines to power different components, such as the boom, stick, and scoop. This mechanism allows for accurate movement and controlled lifting, making it possible to dig, lift, and manipulate loads efficiently. The performance of the hydraulics directly impacts the functionality of the excavator, allowing it to handle heavy materials with effortlessness.

Lastly, the operator's cabin is crucial in ensuring that all excavator parts function cohesively. It contains controls that enable the operator to control the hydraulic system and oversee the movements of the arm, stick, and bucket. A ergonomic cabin improves visibility and comfort, enabling precise operations. When the operator expertly coordinates these components, the whole machine functions smoothly, accomplishing tasks that range from digging foundations to lifting and moving large objects.

Care Guidelines for Excavator Components

Frequent care of excavator components is vital to ensure maximum performance and durability. Start with a periodic inspection of important components such as the tracks, arm, and hydraulic systems. Look for signs of damage or issues, as this can signal potential issues before they become expensive fixes. Eliminate any residue that might accumulate in these locations, as accumulation can lead to unnecessary strain on the machine.

Pay special attention to the hydraulic fluid and ensure that it is at the appropriate levels. Polluted or inadequate hydraulic fluid can significantly affect the excavator's performance and cause early wear on the hydraulic components. It's crucial to replace the fluid and filters as recommended by the maker to keep the hydraulic system functioning efficiently. Oiling moving parts as per the service timeline can also help reduce wear and tear and increase the lifespan of the equipment’s components.

Finally, the lower structure deserves extra attention. This is often one of the most exposed parts of an excavating machine and can suffer from deterioration due to harsh operational environments. Consistently examine the treads for any signs of deterioration, such as splits or fractures, and ensure that the tightness is properly adjusted. This not only improves the machine's mobility but also decreases the chance of track-related issues. Following to these guidelines will greatly contribute to the effectiveness and durability of your excavator.